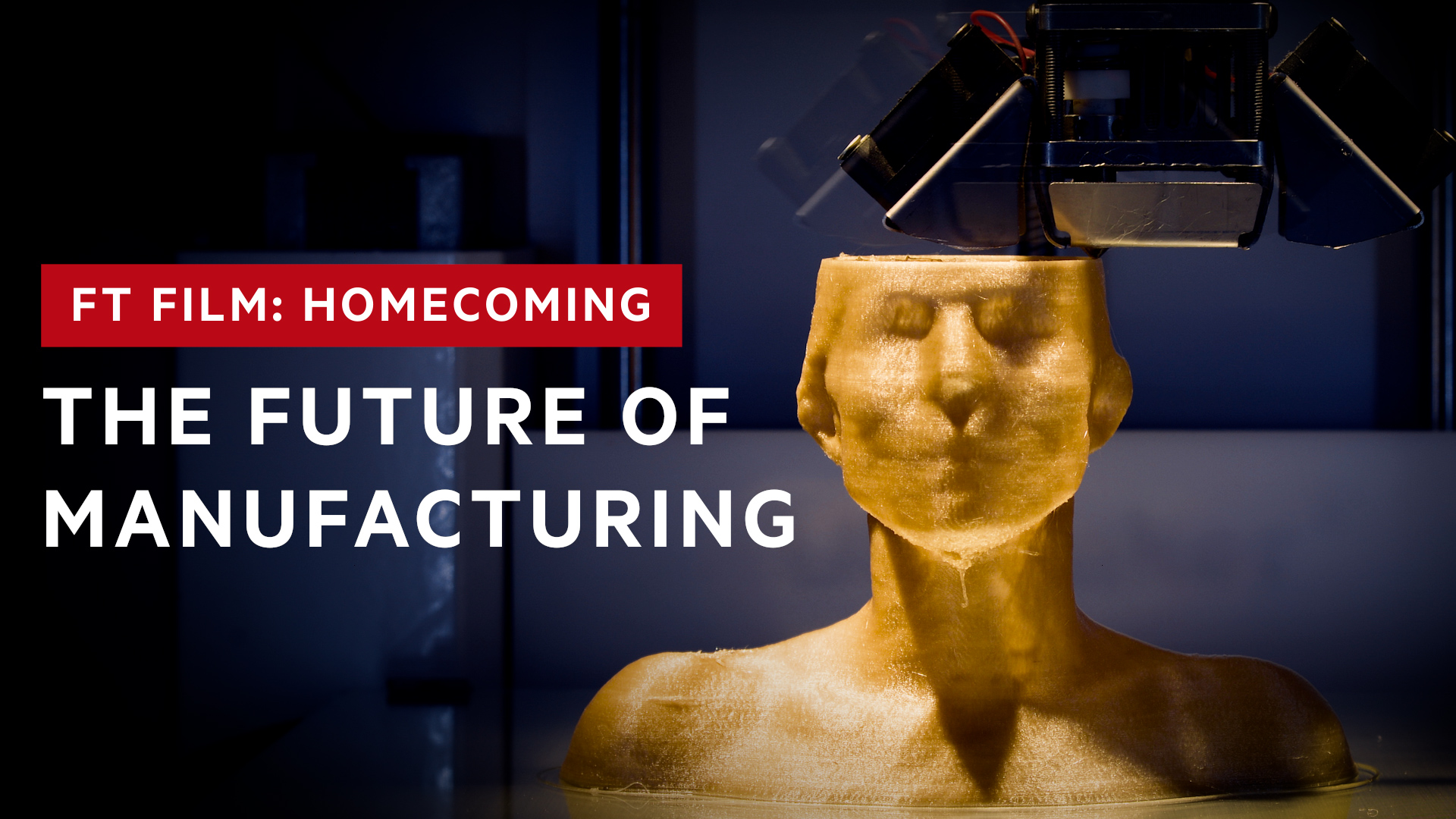

3D printing, also known as additive manufacturing, has emerged as a disruptive technology with the potential to revolutionize the manufacturing industry in the United States. By building objects layer by layer from a digital design, 3D printing offers unprecedented flexibility, customization, and efficiency.

Historical Context

While the concept of 3D printing dates back to the 1980s, it was not until the early 21st century that the technology began to gain widespread attention. Advancements in materials science, computer-aided design (CAD), and manufacturing techniques have made 3D printing more accessible and affordable.

Key Types of 3D Printing

There are several different types of 3D printing technologies, each with its own unique advantages and limitations:

- Fused Deposition Modeling (FDM): The most common type of 3D printing, FDM involves extruding a heated filament to create layers of material.

- Stereolithography (SLA): SLA uses a laser to solidify liquid resin layer by layer, creating highly detailed and accurate parts.

- Selective Laser Sintering (SLS): SLS uses a laser to fuse powdered materials together, creating strong and durable parts.

- Selective Laser Melting (SLM): SLM is similar to SLS but uses a metal powder instead of a plastic or polymer.

Applications of 3D Printing

3D printing has a wide range of applications across various industries, including:

- Manufacturing: 3D printing can be used to produce prototypes, tools, and even finished products.

- Healthcare: 3D printing is used to create custom prosthetics, medical implants, and surgical models.

- Aerospace: 3D printing is used to manufacture lightweight and complex components for aircraft and spacecraft.

- Automotive: 3D printing is used to produce custom parts and prototypes for the automotive industry.

- Consumer Goods: 3D printing is used to produce a wide range of consumer goods, from toys and accessories to custom-designed products.

Benefits of 3D Printing

3D printing offers several benefits over traditional manufacturing methods, including:

- Rapid Prototyping: 3D printing allows for rapid prototyping of new designs, reducing development time and costs.

- Customization: 3D printing enables the production of highly customized products, tailored to specific needs.

- Efficiency: 3D printing can reduce waste and improve manufacturing efficiency.

- Complex Geometries: 3D printing can produce complex geometries that would be difficult or impossible to manufacture using traditional methods.

Challenges and Future Trends

Despite its many benefits, 3D printing also faces challenges, such as:

- Cost: 3D printers and materials can be expensive.

- Speed: 3D printing can be a relatively slow process compared to traditional manufacturing methods.

- Material Limitations: Not all materials can be used for 3D printing.

The future of 3D printing looks promising. As technology continues to advance, we can expect to see even more innovative applications and wider adoption of this transformative technology. 3D printing has the potential to revolutionize manufacturing, healthcare, and other industries, leading to increased efficiency, innovation, and economic growth.